Oil pump installation

-

Install oil pump

-

Remove any old packing (FIPG) material and be careful not to drop any oil on the contact surfaces of the oil pump and cylinder block.

- Using a razor blade gasket scraper, remove all the old packing (FIPG) material from the gasket surfaces and sealing groove.

- Thoroughly clean all components to remove all the debris.

- Using a non-residue solvent, clean both sealing surfaces.

-

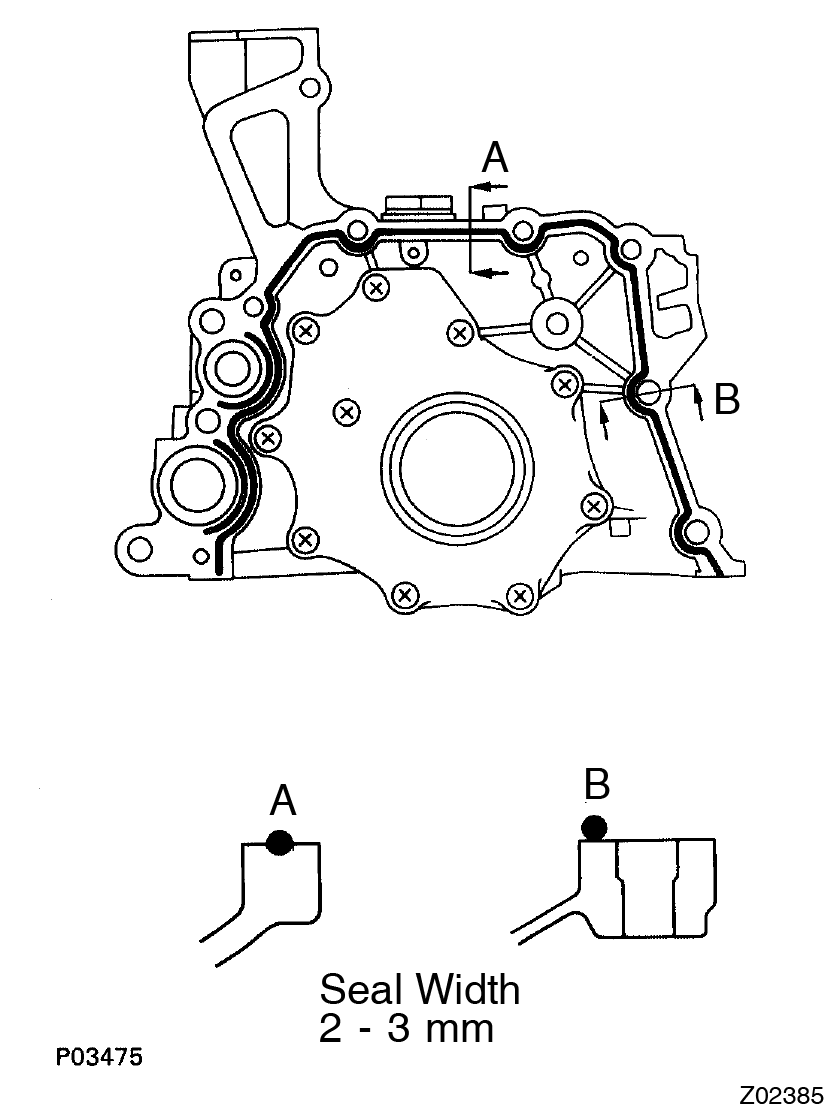

Apply seal packing to the oil pump as shown in the illustration.

Seal packing:

Part No. 08826-00080 or equivalent- Install a nozzle that has been cut to a 2 - 3 mm (0.08 - 0.12 in.) opening.

Avoid applying an excessive amount to the surface. Be particularly careful near oil passages.

- Parts must be assembled within 5 minutes of application. Otherwise the material must be removed and reapplied.

- Immediately remove nozzle from the tube and reinstall cap.

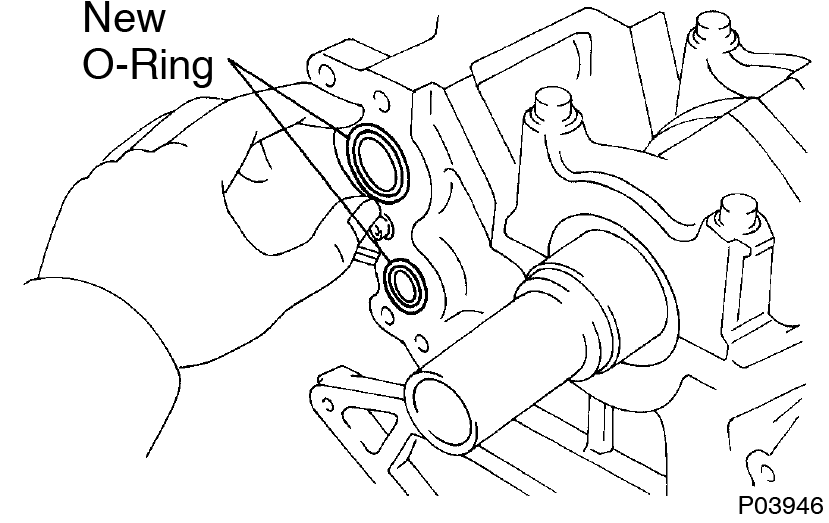

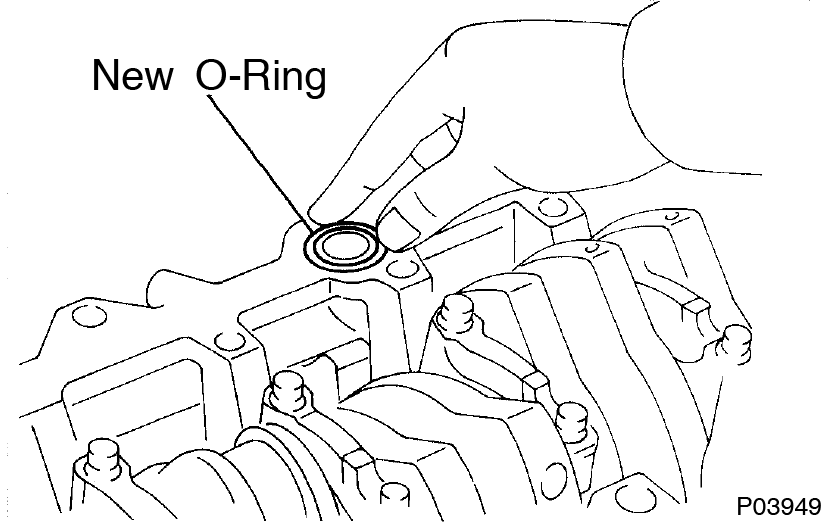

- Place 2 new O-rings in position on the cylinder block.

-

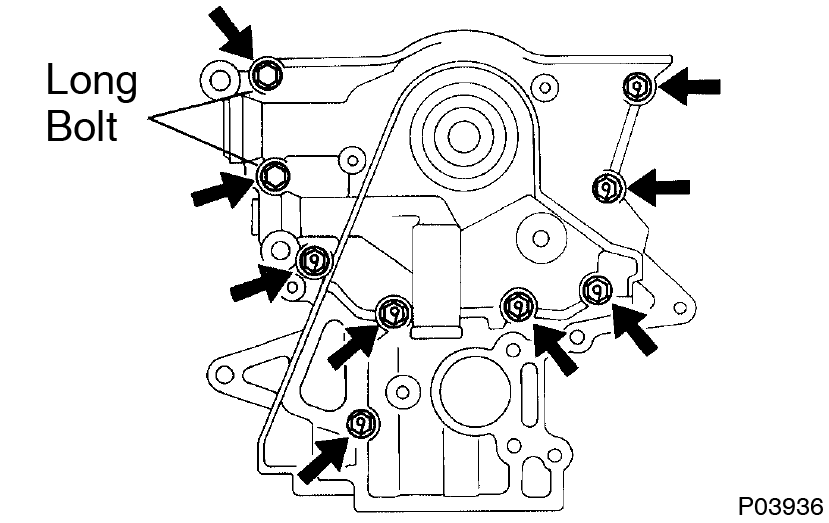

Install the oil pump with the 9 bolts.

Torque: 21 N·m (210 kgf·cm, 15 ft·lbf)

Torque: 21 N·m (210 kgf·cm, 15 ft·lbf)

-

Remove any old packing (FIPG) material and be careful not to drop any oil on the contact surfaces of the oil pump and cylinder block.

-

Install No.1 oil pan

-

Remove any old packing (FIPG) material and be careful not to drop any oil on the contact surfaces of the No.1 oil pan and cylinder block.

- Using a razor blade and gasket scraper, remove all the old packing (FIPG) material from the gasket surfaces and sealing groove.

- Thoroughly clean all components to remove all the debris.

- Using a non-residue solvent, clean both sealing surfaces.

Do not use a solvent which will affect the painted surfaces. -

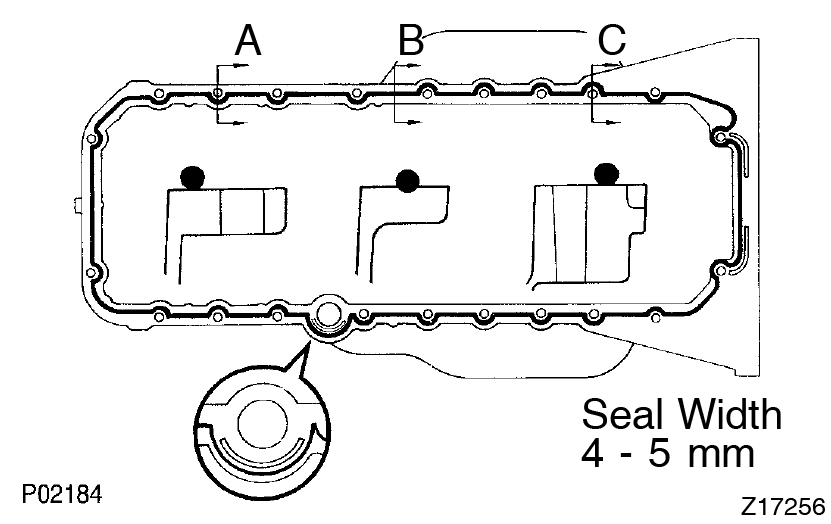

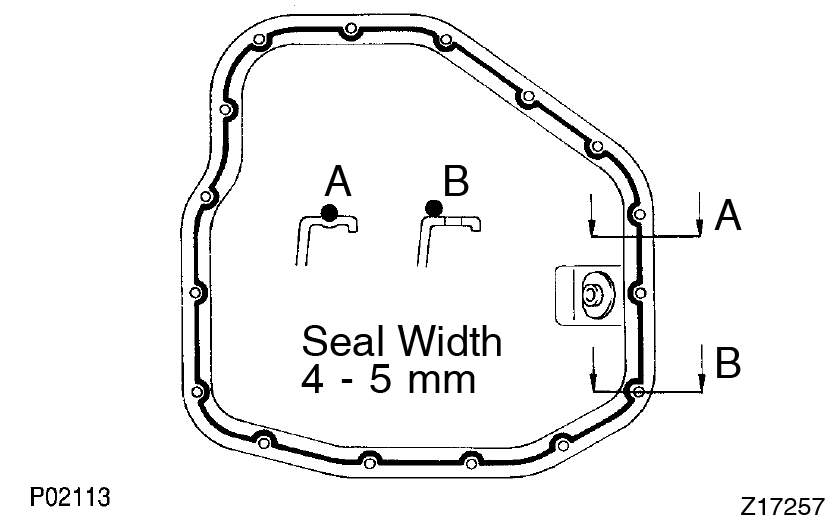

Apply seal packing to the No.1 oil pan as shown in the illustration.

Seal packing:

Seal packing:

Parts No. 08826-00080 or equivalent- Install a nozzle that has been cut to a 4 - 5 mm (0.16 - 0.20 in.) opening.

Avoid applying an excessive amount to the surface.- Parts must be assembled within 5 minutes of application. Otherwise the material must be removed and reapplied.

- Immediately remove nozzle from the tube and reinstall cap.

-

Place a new O-ring in the position on the cylinder block.

-

Install the No.1 oil pan with the 22 bolts.

Torque:

12 mm head

21 N·m (210 kgf·cm, 15 ft·lbf)

14 mm head

39 N·m (400 kgf·cm, 29 ft·lbf)

-

Remove any old packing (FIPG) material and be careful not to drop any oil on the contact surfaces of the No.1 oil pan and cylinder block.

-

2JZ-GTE

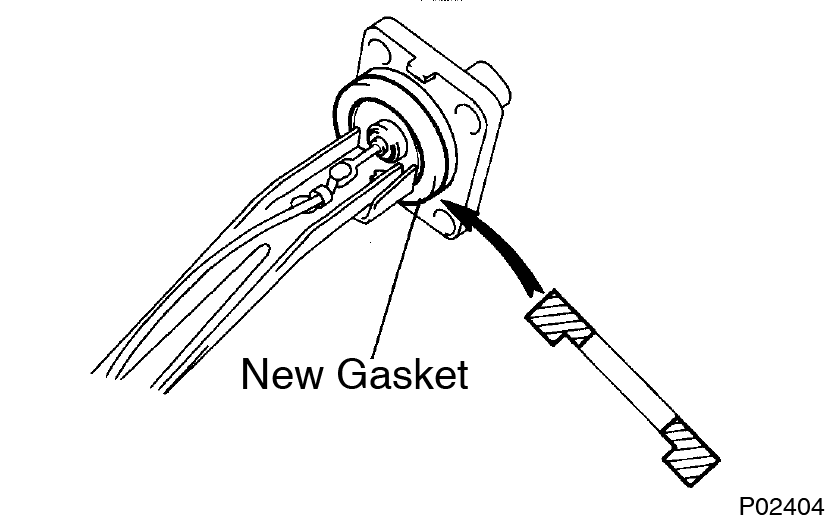

Install turbo oil outlet pipe-

Install a new gasket and the oil outlet pipe with the 2 nuts.

Torque: 27 N·m (280 kgf·cm, 20 ft·lbf) - Connect the 2 turbo oil outlet hoses.

-

Install a new gasket and the oil outlet pipe with the 2 nuts.

-

Install oil pan baffle plate

Torque: 8.8 N·m (90 kgf·cm, 78 in.·lbf) -

Install oil strainer

Install a new gasket and the oil strainer with the bolt and 2 nuts.

Torque: 8.8 N·m (90 kgf·cm, 78 in.·lbf) -

Install No.2 oil pan

-

Remove any old packing (FIPG) material and be careful not to drop any oil on the contact surfaces of the No.1 and No.2 oil pans.

- Using a razor blade and gasket scraper, remove all the old packing (FIPG) material from the gasket surfaces and sealing groove.

- Thoroughly clean all components to remove all the debris.

- Using a non-residue solvent, clean both sealing surfaces.

Do not use a solvent which will affect the painted surfaces. -

Apply seal packing to the No.2 oil pan as shown in the illustration.

Seal packing:

Seal packing:

Part No. 08826-00080 or equivalent- Install a nozzle that has been cut to a 4 - 5 mm (0.16 - 0.20 in.) opening.

Avoid applying an excessive amount to the surface.- Parts must be assembled within 5 minutes of application. Otherwise the material must be removed and reapplied.

- Immediately remove nozzle from the tube and reinstall cap.

-

Install the No.2 oil pan with the 14 bolts and 2 nuts.

Torque: 8.8 N·m (90 kgf·cm, 78 in.·lbf)

-

Remove any old packing (FIPG) material and be careful not to drop any oil on the contact surfaces of the No.1 and No.2 oil pans.

-

Install oil level sensor

- Install a new gasket to the level sensor.

-

Install the level sensor with the 4 bolts.

Torque: 5.4 N·m (55 kgf·cm, 48 in.·lbf) - Connect the level sensor connector.

-

Install oil dipstick guide and dipstick

- Install a new O-ring on the dipstick guide.

- Apply new oil to the O-ring.

- Connect the dipstick guide end to the dipstick tube of the oil pan.

- Install the dipstick guide with the bolt.

- Install the dipstick.

-

Install crankshaft timing pulley and idler pulley

(2JZ-GE: See page EM-19 )

(2JZ-GTE: See page EM-21 ) -

2JZ-GTE M/T:

Install drive belt tensioner bracket

Torque: 27 N·m (280 kgf·cm, 20 ft·lbf) -

Install timing belt

(2JZ-GE: See page EM-19 )

(2JZ-GTE: See page EM-21 ) -

Install crankshaft position sensor

Torque: 9.0 N·m (90 kgf·cm, 80 in.·lbf) - Install generator (See page CH-18 )

- Remove engine stand from engine

-

Assembly engine and transmission

(2LZ-GE: See page AT-24)

(2JZ-GTE: See page EM-65 ) -

Install engine with transmission

(2JZ-GE: See page EM-57 )

(2JZ-GTE: See page EM-65 )

This guide is based on the book edition Toyota (RM502U, 1997)

Volksbibliothek, info@volksbibliothek.com

Back Next