Timing belt inspection

-

Inspect timing belt

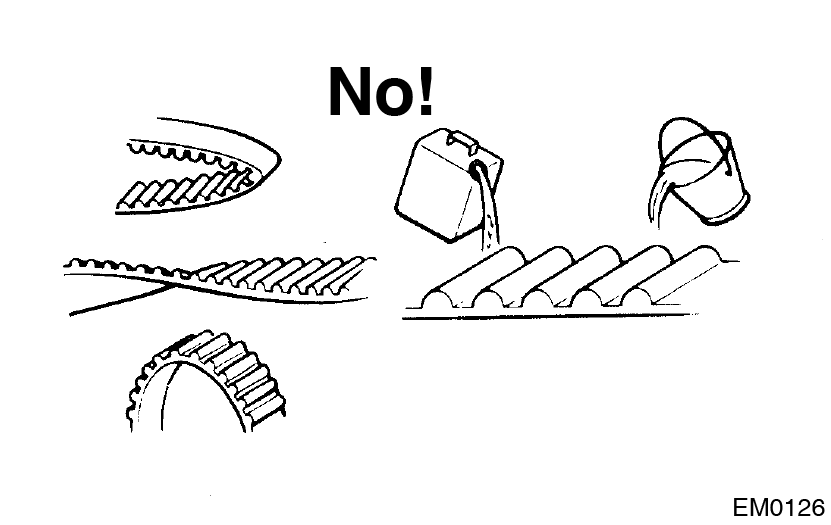

If there are any defects, as shown in the illustrations, check the following points.

- Do not bend, twist or turn the timing belt inside out.

- Do not allow the timing belt to come into contact with oil, water or steam.

- Do not utilize timing belt tension when installing or removing the mount bolt of the camshaft timing pulley.

-

Premature parting

- Check for proper installation.

- Check the timing cover gasket for damage and proper installation.

- If the belt teeth are cracked or damaged, check to see if either camshaft is locked.

- If there is noticeable wear or cracks on the belt face, check to see if there are nicks on the side of the idler pulley lock.

- If there is wear or damage on only one side of the belt, check the belt guide and the alignment of each pulley.

-

If there is noticeable wear on the belt teeth, check timing cover for damage and check gasket has been installed correctly and for foreign material on the pulley teeth.

If necessary, replace the timing belt.

-

Inspect idler pulley

-

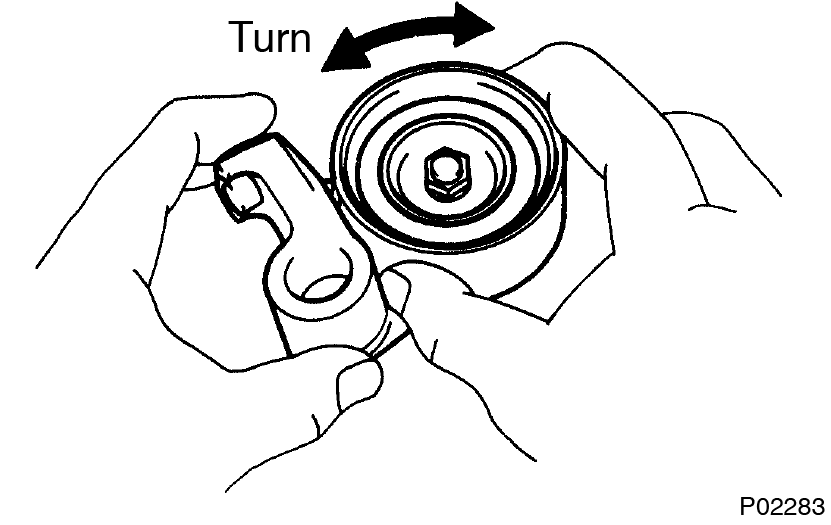

Check the turning smoothness of the idler pulley.

If necessary, replace the idler pulley.

-

Check the turning smoothness of the tensioner.

If necessary, replace the tensioner.

-

Check the turning smoothness of the idler pulley.

-

Inspect timing belt tensioner

-

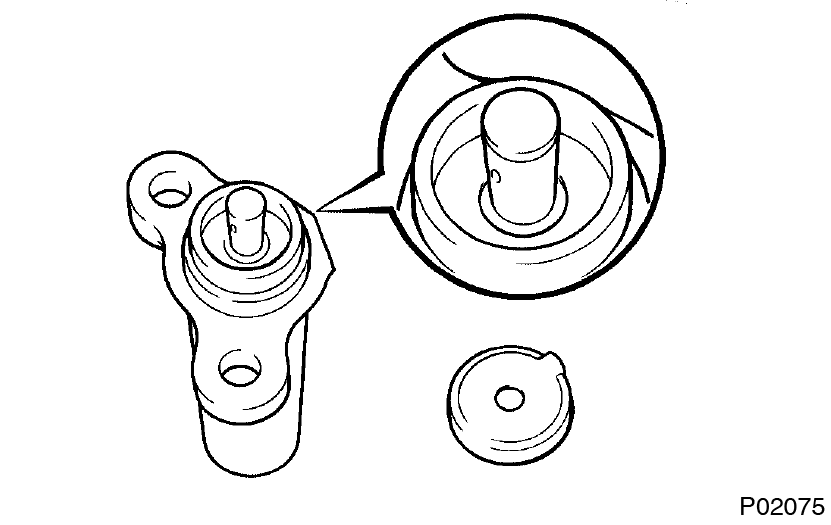

Visually check tensioner for oil leakage.

If there is only the faintest trace of oil on the seal on the push rod side, the tensioner is all right.

If leakage is found, replace tensioner.

-

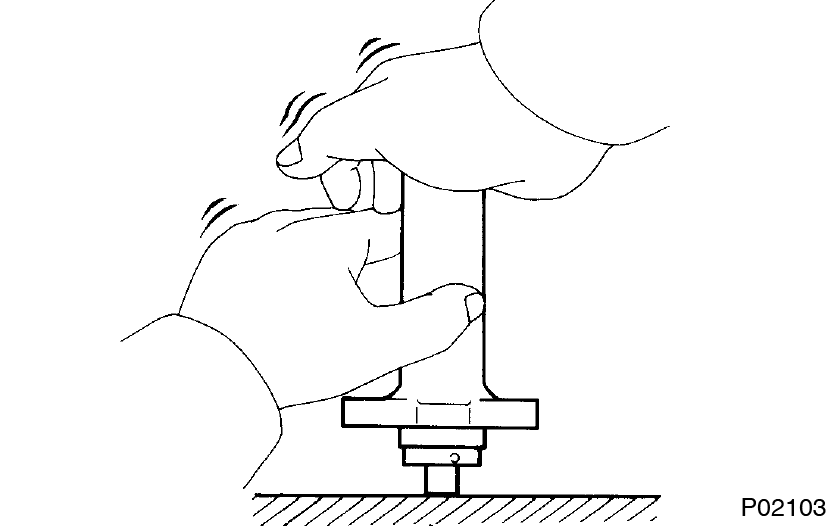

Hold the tensioner with both hands and push the push rod strongly against the floor or wall to check that it doesn’t move.

If the push rod moves, replace the tensioner.

-

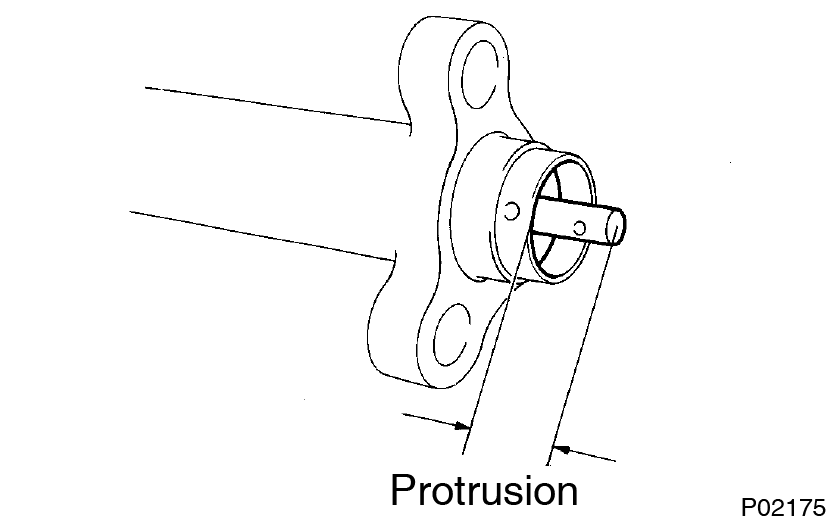

Measure the protrusion of the push rod from the housing end.

Protrusion: 8.0-8.8 mm (0.315-0.346 in.)

If the protrusion is not as specified, replace the tensioner.

-

Visually check tensioner for oil leakage.

-

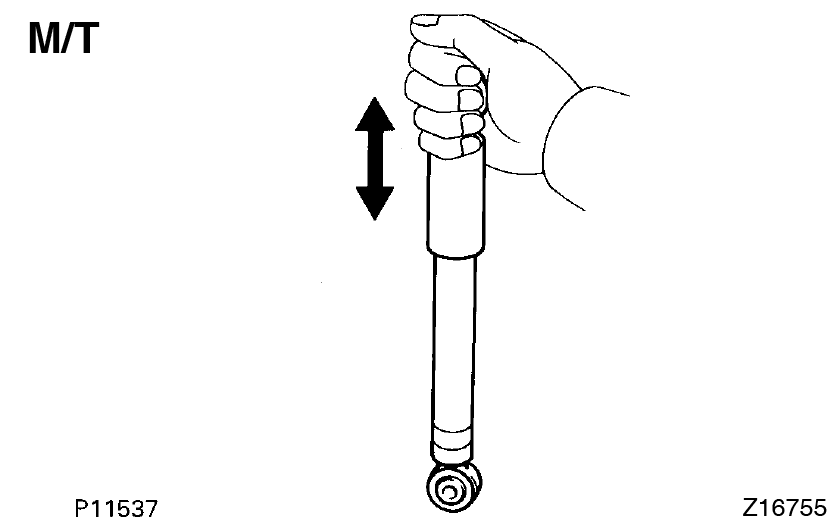

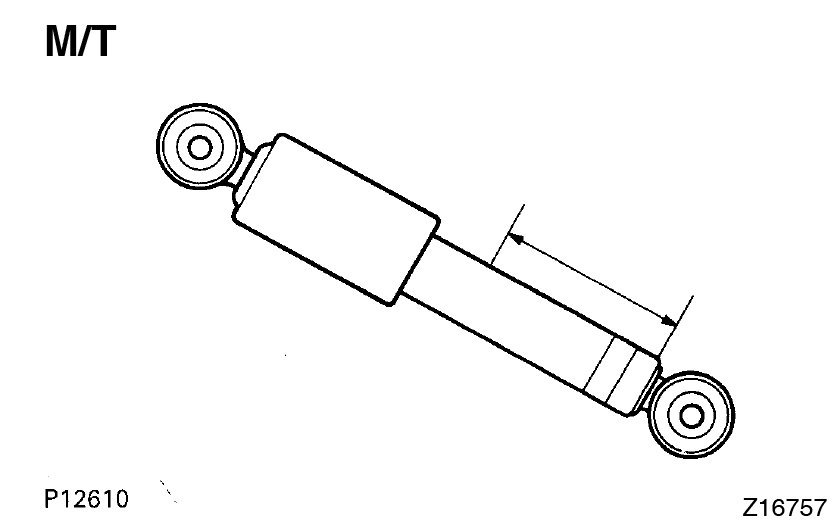

M/T:

Inspect drive belt tension damper

Compress and extend the tension damper rod and check that there is no abnormal resistance or unusual operation sounds.

If there is any abnormality, replace the tension damper with a new one. When discarding the tension damper, use the following procedure.

When discarding the tension damper, use the following procedure.- Fully extend the damper rod.

- Using a drill, make a hole in the cylinder as shown to release the gas inside.

The gas coming out is harmless, but be careful of the chips which may fly up when drilling.

This guide is based on the book edition Toyota (RM502U, 1997)

Volksbibliothek, info@volksbibliothek.com

Back Next