Compression

If there is lack of power, excessive oil consumption or poor fuel economy, measure the compression pressure.

-

Warm up and stop engine

Allow the engine to warm up to normal operating temperature. - Disconnect camshaft position sensor connectors

- Remove ignition coils assemblies (See page IG-6 )

- Remove spark plugs

-

Check cylinder compression

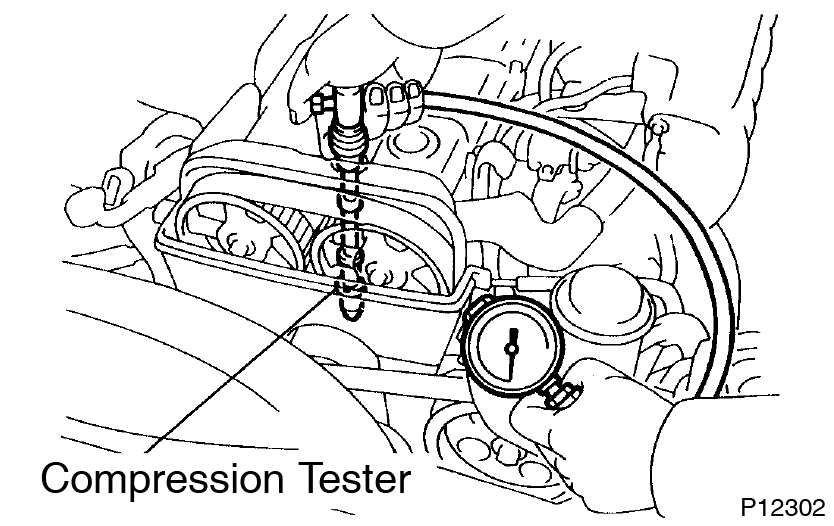

- Insert a compression tester into the spark plug hole.

-

While cranking the engine, measure the compression pressure.

Always use a fully charged battery to obtain engine revolutions of 250 rpm or more. -

Repeat steps (a) through (b) for each cylinder.

This measurement must be done in as short a time as possible.Standard pressure:

1,079 kPa (11.0 kgf/cm2 , 156 psi) or more

Minimum pressure:

883 kPa (9.0 kgf/cm2 , 128 psi)

Difference between each cylinder:

98 kPa (1.0 kgf/cm2 , 14 psi) or less -

If the cylinder compression in 1 or more cylinders is low, pour a small amount of engine oil into the cylinder through the spark plug hole and repeat steps (a) through (b) for the cylinder with low compression.

- If adding oil helps the compression, it is likely that the piston rings and/or cylinder bore are probably worn or damaged.

- If pressure stays low, a valve may be sticking or seating improper, or there may be leakage past the gasket.

- Reinstall spark plugs

- Reinstall ignition coils assemblies (See page IG-7 )

- Reconnect camshaft position sensor connectors

This guide is based on the book edition Toyota (RM502U, 1997)

Volksbibliothek, info@volksbibliothek.com

Back Next