Cylinder head inspection

-

Clean top surfaces of pistons and cylinder block

-

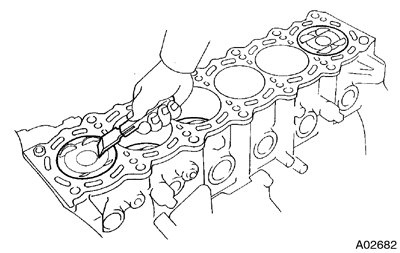

Turn the crankshaft, and bring each piston to top dead center (TDC). Using a gasket scraper, remove all the carbon from the piston top surface.

-

Using a gasket scraper, remove all the gasket material from the top surface of the cylinder block.

-

Using compressed air, blow carbon and oil from the bolt holes.

Protect your eyes when using high pressure-compressed air.

-

Turn the crankshaft, and bring each piston to top dead center (TDC). Using a gasket scraper, remove all the carbon from the piston top surface.

-

Clean cylinder head

-

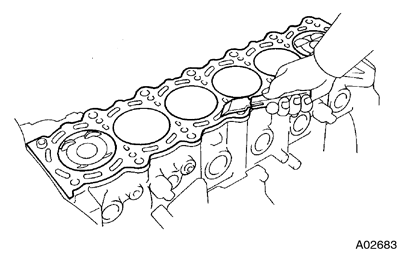

Remove gasket material

Using a gasket scraper, remove all the gasket material from the cylinder block surface. Be careful not to scratch the cylinder block contact surface.

Be careful not to scratch the cylinder block contact surface. -

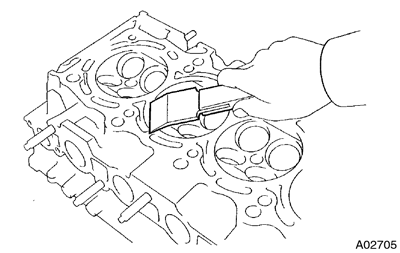

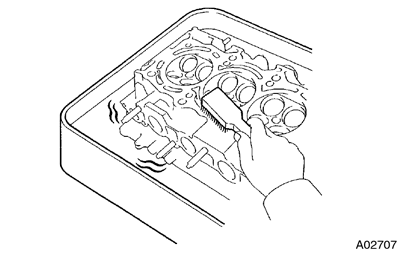

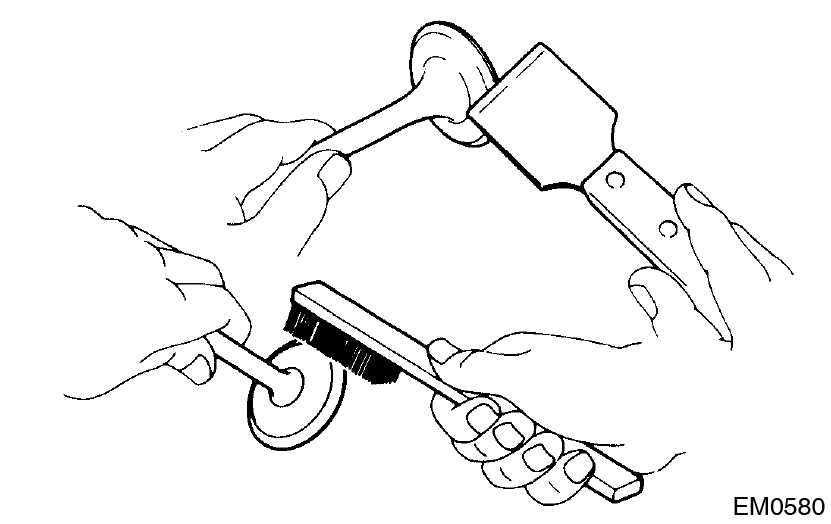

Clean combustion chambers

Using a wire brush, remove all the carbon from the combustion chambers. Be careful not to scratch the cylinder block contact surface.

Be careful not to scratch the cylinder block contact surface. -

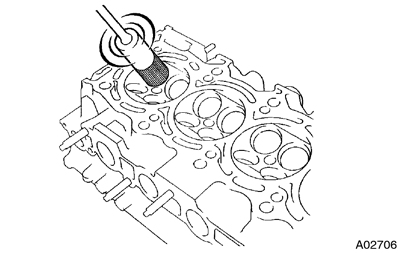

Clean valve guide bushings

Using a valve guide bushing brush and solvent, clean all the guide bushings.

-

Clean cylinder head

Using a soft brush and solvent, thoroughly clean the cylinder head.

-

Remove gasket material

-

Inspect cylinder head

-

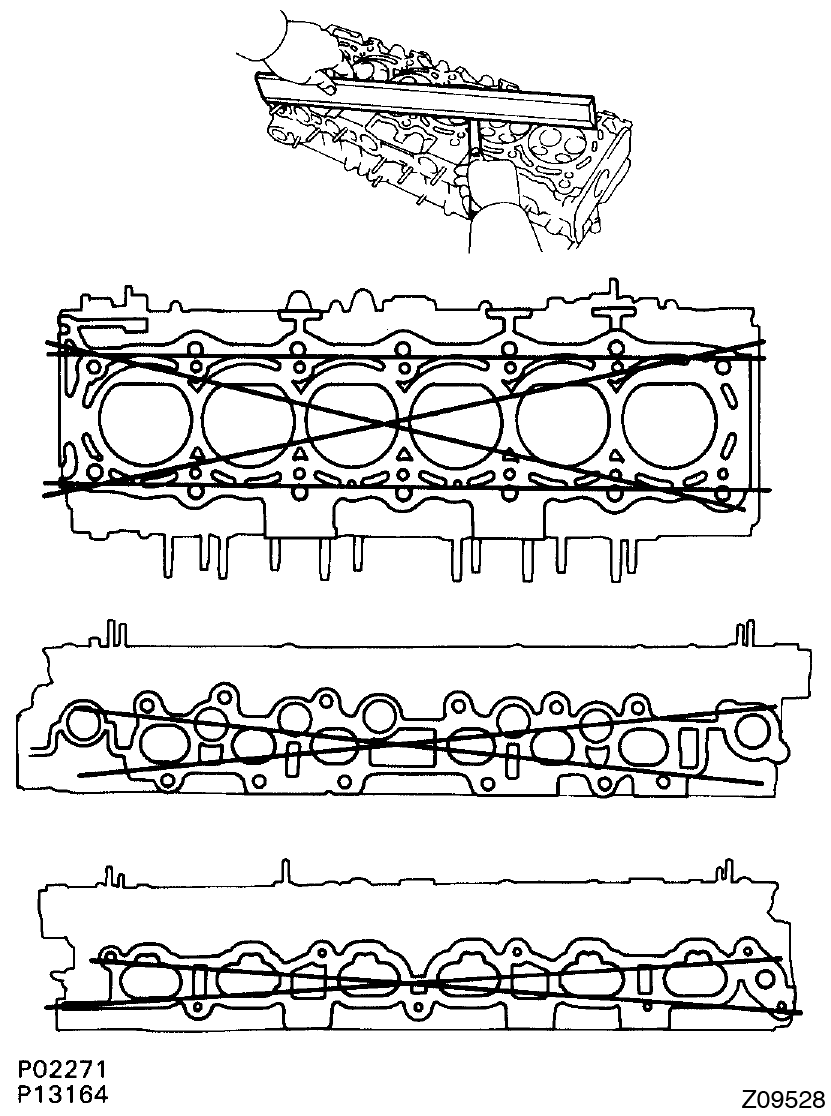

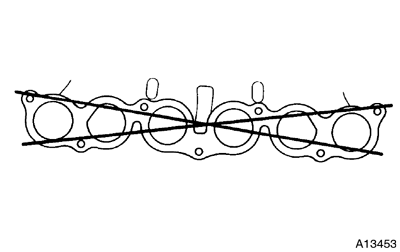

Inspect for flatness

Using precision straight edge and feeler gauge, measure the surfaces contacting the cylinder block, intake and exhaust manifolds for warpage.

Maximum warpage: 0.10 mm (0.0039 in.) If warpage is greater than maximum, replace the cylinder head.

If warpage is greater than maximum, replace the cylinder head.

-

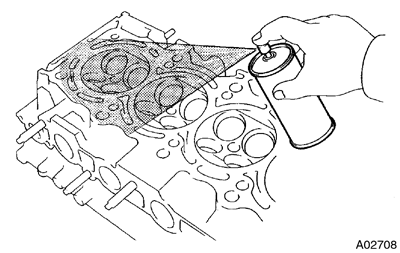

Inspect for cranks

Using a dye penetrant, check the combustion chamber, intake ports, exhaust ports and cylinder block surface for cracks. If cracked, replace the cylinder head.

If cracked, replace the cylinder head.

-

Inspect for flatness

-

Clean valves

-

Using a gasket scraper, chip off any carbon from the valve head.

- Using a wire brush, thoroughly clean the valve.

-

Using a gasket scraper, chip off any carbon from the valve head.

-

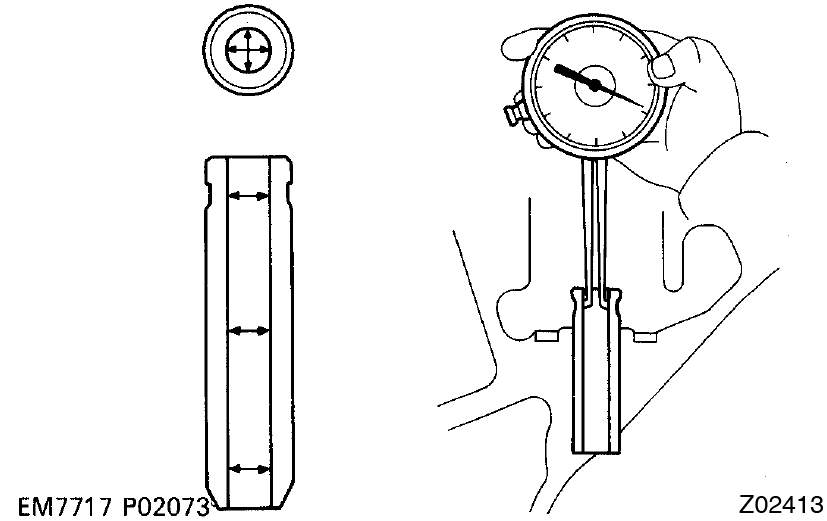

Inspect valve stems and guide bushings

-

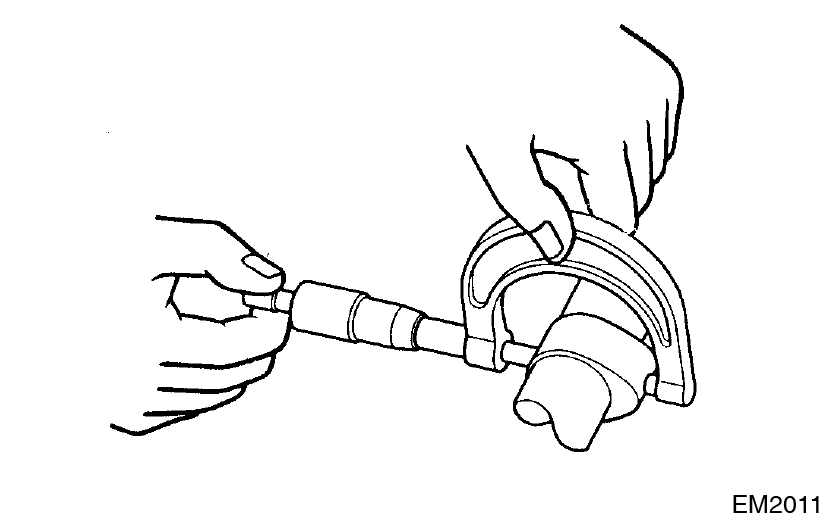

Using a caliper gauge, measure the inside diameter of the guide bushing.

Bushing inside diameter:

6.010 - 6.030 mm (0.2366 - 0.2374 in.)

-

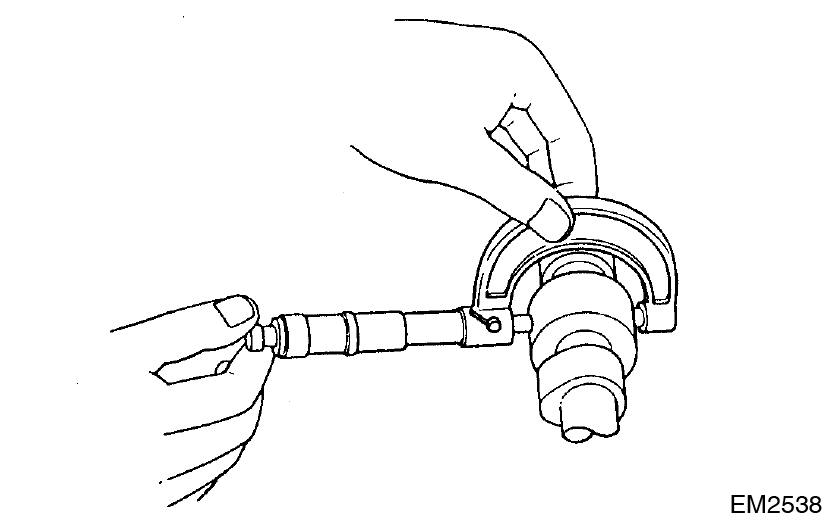

Using a micrometer, measure the diameter of the valve stem.

Valve stem diameter:

Intake 5.970 - 5.985 mm (0.2350 - 0.2356 in.)

Exhaust 5.965 - 5.980 mm (0.2348 - 0.2354 in.)

-

Subtract the valve stem diameter measurement from the guide bushing inside diameter measurement.

Standard oil clearance:

Intake 0.025 - 0.060 mm (0.0010 - 0.0024 in.)

Exhaust 0.030 - 0.065 mm (0.0012 - 0.0026 in.)

Maximum oil clearance:

Intake 0.08 mm (0.0031 in.)

Exhaust 0.10 mm (0.0039 in.)

-

Using a caliper gauge, measure the inside diameter of the guide bushing.

-

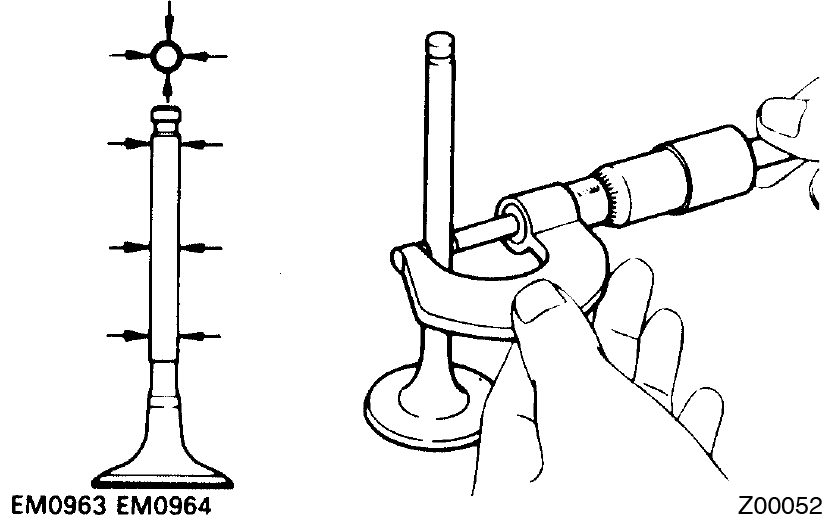

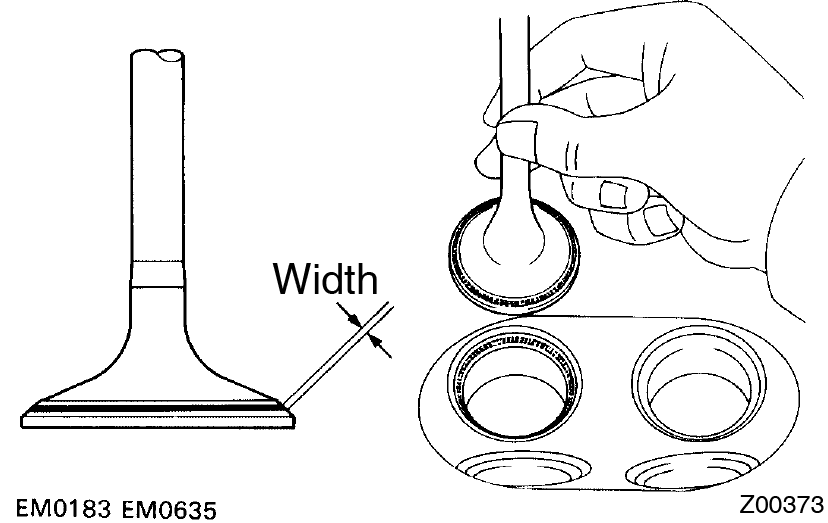

Inspect and grind valves

-

Grind the valve enough to remove pits and carbon.

-

Check that the valve is ground to the correct valve face angle.

Valve face angle: 44.5° -

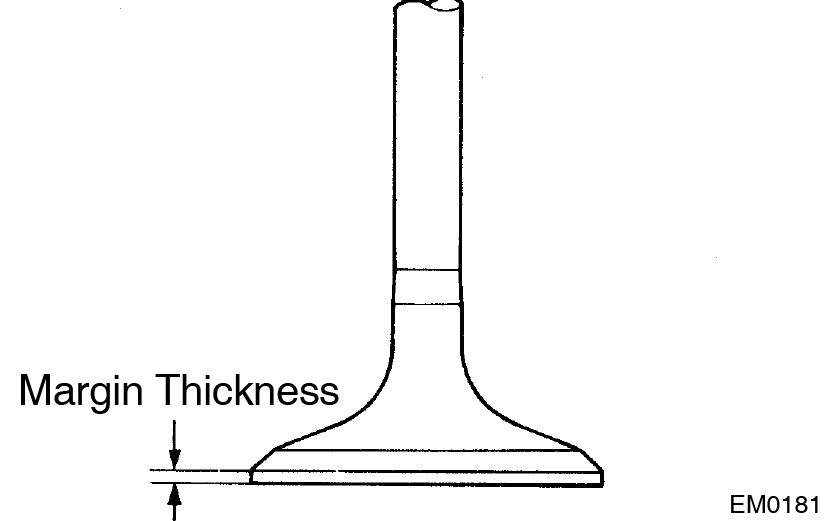

Check the valve head margin thickness.

Standard margin thickness:

Standard margin thickness:

0.8 - 1.2 mm (0.031 - 0.047 in.)

Minimum margin thickness:

0.5 mm (0.020 in.)

If the margin thickness is less than minimum, replace the valve. -

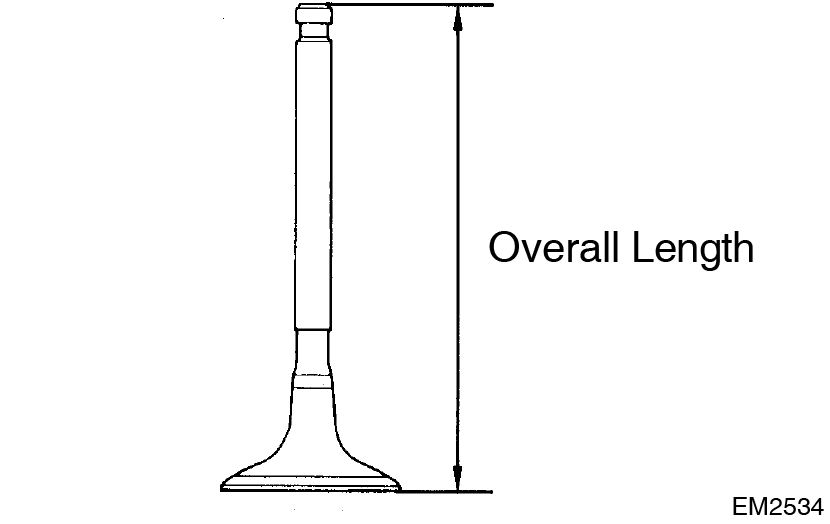

Check the valve overall length.

Standard overall length:

Standard overall length:

Intake 98.29 - 98.79 mm (3.8697 - 3.8894 in.)

Exhaust 98.84 - 99.34 mm (3.8913 - 3.9110 in.)

Minimum overall length:

Intake 98.19 mm (3.8657 in.)

Exhaust 98.74 mm (3.8874 in.)

If the overall length is less than minimum, replace the valve. -

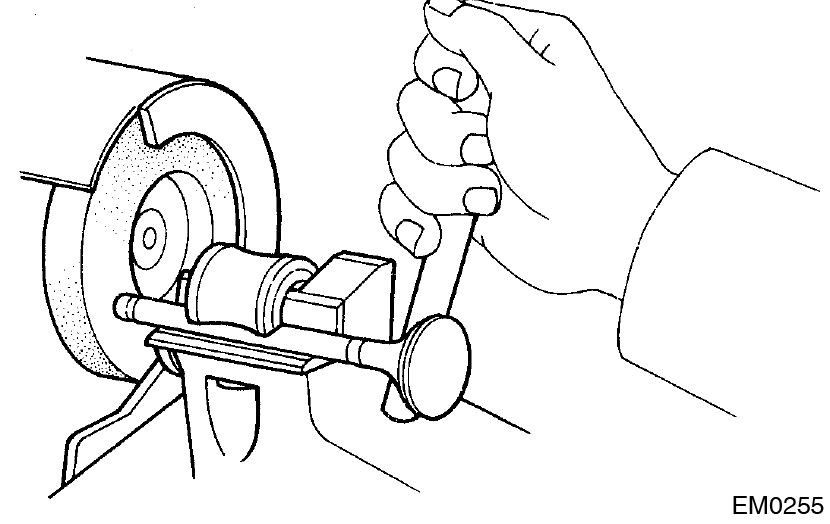

Check the surface of the valve stem tip for wear.

If the valve stem tip is worn, resurface the tip with a grinder or replace the valve.

Do not grind off more than the minimum overall length.

If the valve stem tip is worn, resurface the tip with a grinder or replace the valve.

Do not grind off more than the minimum overall length.

-

Grind the valve enough to remove pits and carbon.

-

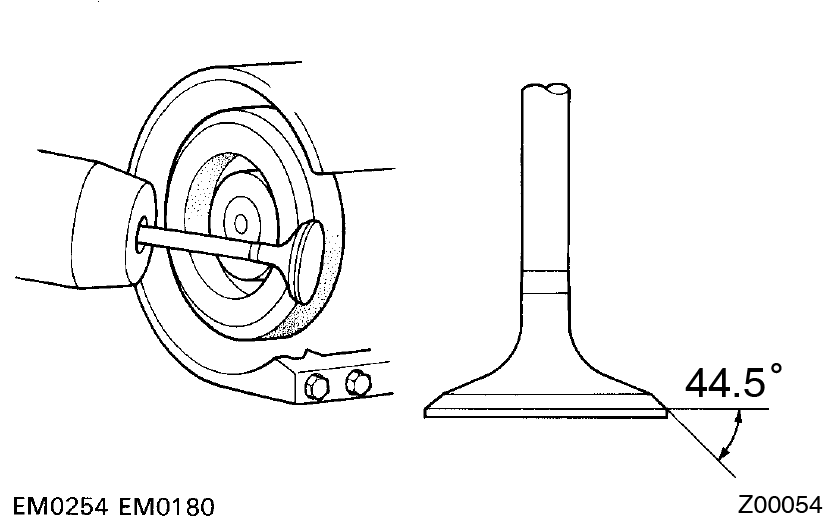

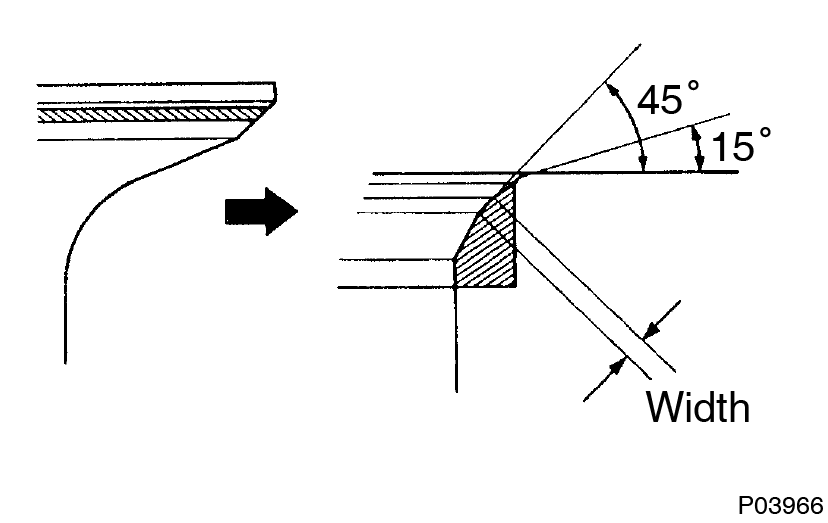

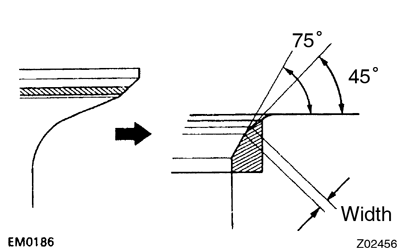

Inspect and clean valve seats

-

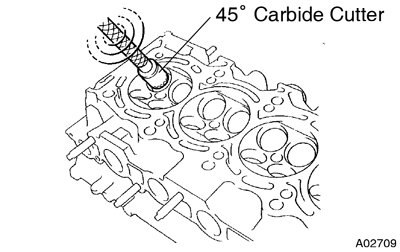

Using a 45° carbide cutter, resurface the valve seats. Remove only enough metal to clean the seats.

-

Check the valve seating position.

Apply a thin coat of prussian blue (or white lead) to the valve face. Lightly press the valve against the seat. Do not rotate the valve.

-

Check the valve face and seat for the following:

- If blue appears 360° around the face, the valve is concentric. If not, replace the valve.

- If blue appears 360° around the valve seat, the guide and face are concentric. If not, resurface the seat.

-

Check that the seat contact is in the middle of the valve face with the following width:

Intake 1.0 - 1.4 mm (0.039 - 0.055 in.)

Exhaust 1.2 - 1.6 mm (0.047 - 0.063 in.)

If not, correct the valve seats as follows:

-

If the seating is too high on the valve face, use 15° and 45° cutters to correct the seat.

-

If the seating is too low on the valve face, use 75° and 45° cutters to correct the seat.

-

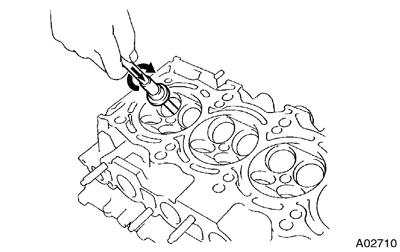

Hand-lap the valve and valve seat with an abrasive compound.

- After hand-lapping, clean the valve and valve seat.

-

Using a 45° carbide cutter, resurface the valve seats. Remove only enough metal to clean the seats.

-

Inspect valve springs

-

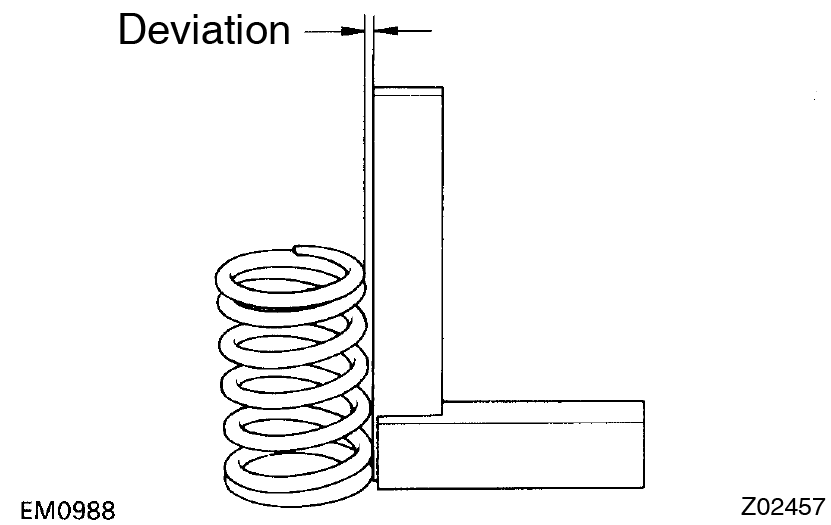

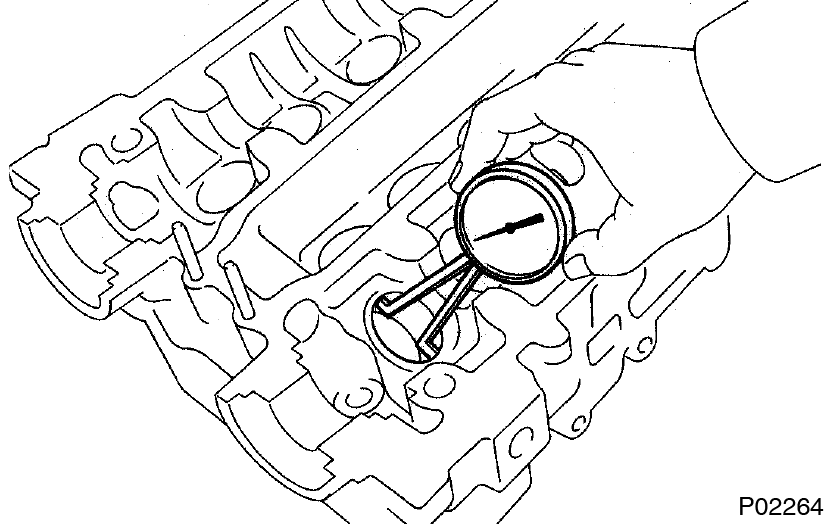

Using a steel square, measure the deviation of the valve spring.

Maximum deviation: 2.0 mm (0.079 in.)

If deviation is greater than maximum, replace the valve spring.

-

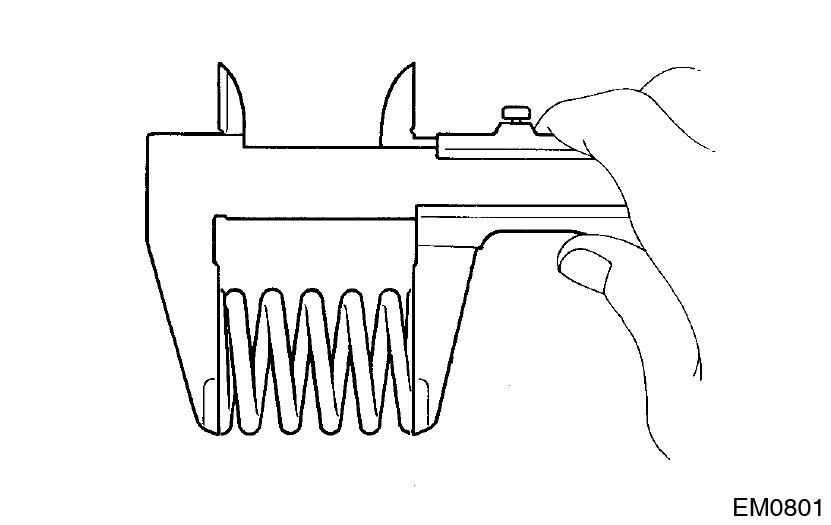

Using vernier calipers, measure the free length of the valve spring.

Free length:

If the free length is not as specified, replace the valve spring.Pink painted mark 43.71 mm (1.7209 in.) Yellow painted mark 44.10 mm (1.7362 in.)

-

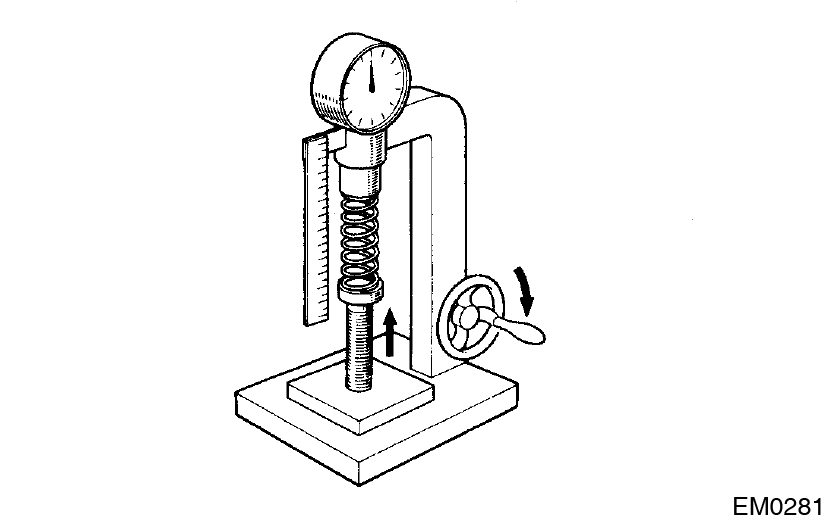

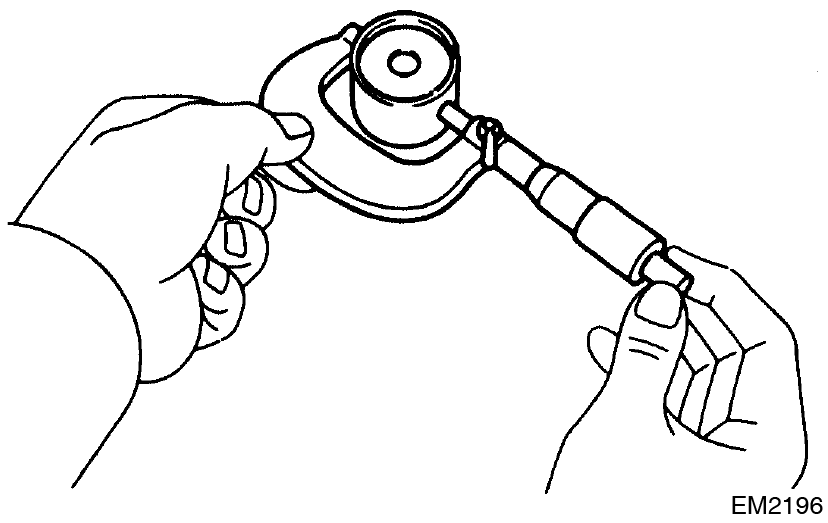

Using a spring tester, measure the tension of the valve spring at the specified installed length.

Installed tension:

186.2 - 205.8 N (19.0 - 21.0 kgf, 41.9 - 46.3 lbf) at 34.5 mm (1.358 in.)

If the installed tension is not as specified, replace the valve spring.

-

Using a steel square, measure the deviation of the valve spring.

-

Inspect camshafts and bearings

-

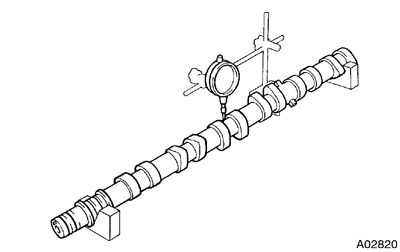

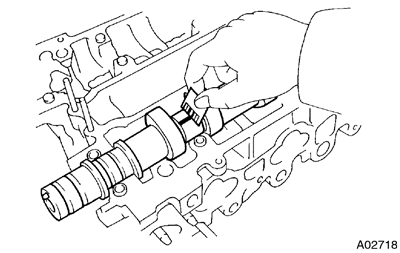

Place the camshaft on V-blocks.

-

Using a dial indicator, measure the circle runout at the center journal.

Maximum circle runout: 0.08 mm (0.0031 in.)

If the circle runout is greater than maximum, replace the camshaft. -

Using a micrometer, measure the cam lobe height.

Standard cam lobe height:

Standard cam lobe height:

Intake 44.310 - 44.360 mm (1.7445 - 1.7465 in.)

Exhaust 44.250 - 44.350 mm (1.7421 - 1.7461 in.)

Minimum cam lobe height:

Intake 44.16 mm (1.7386 in.)

Exhaust 44.10 mm (1.7362 in.)

If the cam lobe height is less than minimum, replace the camshaft. -

Using a micrometer, measure the journal diameter.

Journal diameter:

Journal diameter:

28.949 - 28.965 mm (1.1397 - 1.1404 in.)

If the journal diameter is not as specified, check the oil clearance. -

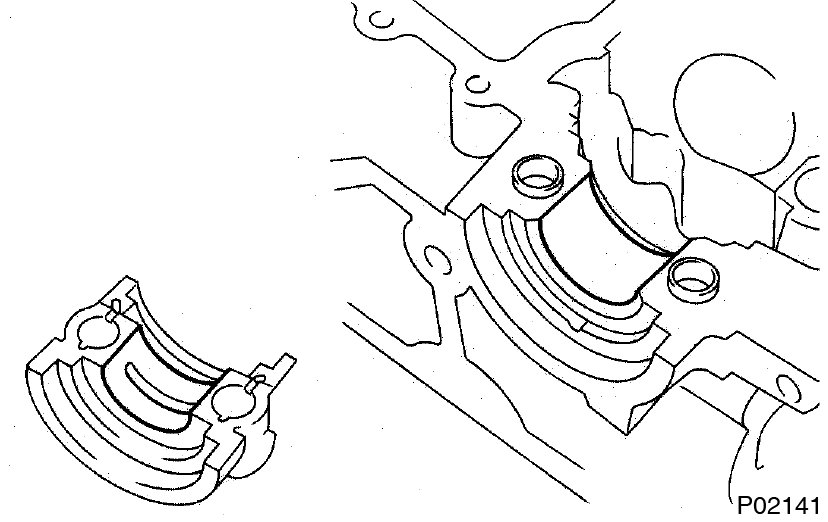

Check the bearings for flaking and scoring.

If the bearings are damaged, replace the bearing caps and cylinder head as a set.

If the bearings are damaged, replace the bearing caps and cylinder head as a set.

-

Clean the bearing caps and camshaft journals.

- Place the camshafts on the cylinder head.

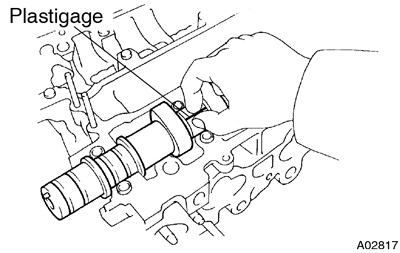

- Lay a strip of Plastigage across each of the camshaft journals.

-

Install the bearing caps. (See page EM-45)

Torque: 20 N·m (200 kgf·cm, 14 ft·lbf)Do not turn the camshaft. - Remove the bearing caps.

-

Measure the Plastigage at its widest point.

Standard oil clearance:

Standard oil clearance:

0.035 - 0.072 mm (0.0014 - 0.0028 in.)

Maximum oil clearance:

0.10 mm (0.0039 in.)

If the oil clearance is greater than maximum, replace the camshaft. If necessary, replace the bearing caps and cylinder head as a set. - Completely remove the Plastigage.

-

Install the camshafts. (See page EM-45)

-

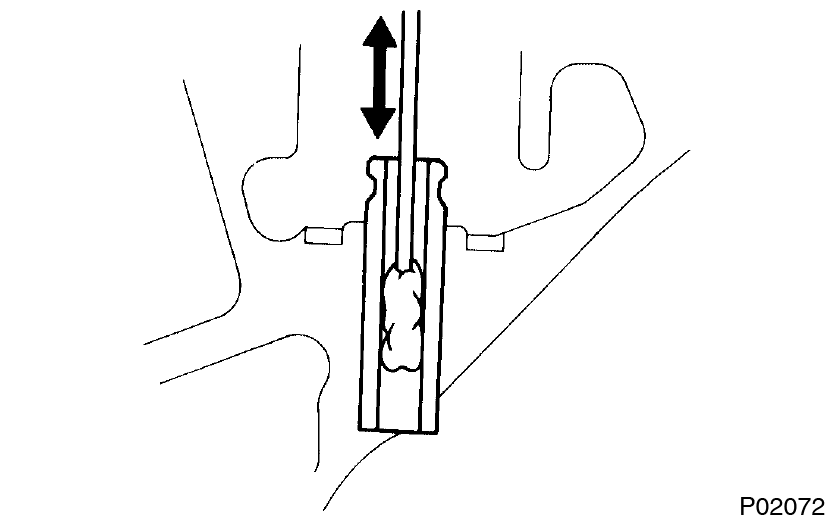

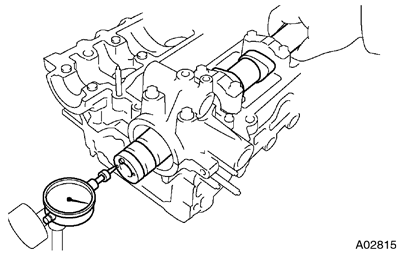

Using a dial indicator, measure the thrust clearance while moving the camshaft back and forth.

Standard thrust clearance:

0.080 - 0.190 mm (0.0031 - 0.0075 in.)

Maximum thrust clearance:

0.30 mm (0.0118 in.)

If the thrust clearance is greater than maximum, replace the camshaft. If necessary, replace the bearing caps and cylinder head as a set.

-

Place the camshaft on V-blocks.

-

Inspect valve lifters and lifter bores

-

Using a caliper gauge, measure the lifter bore diameter of the cylinder head.

Lifter bore diameter:

31.000 - 31.016 mm (1.2205 - 1.2211 in.)

-

Using a micrometer, measure the lifter diameter.

Lifter diameter:

30.966 - 30.976 mm (1.2191 - 1.2195 in.)

-

Subtract the lifter diameter measurement from the lifter bore diameter measurement.

Standard oil clearance:

0.024 - 0.050 mm (0.0009 - 0.0020 in.)

Maximum oil clearance:

0.07 mm (0.0028 in.)

If the oil clearance is greater than maximum, replace the lifter.

If necessary, replace the cylinder head.

-

Using a caliper gauge, measure the lifter bore diameter of the cylinder head.

-

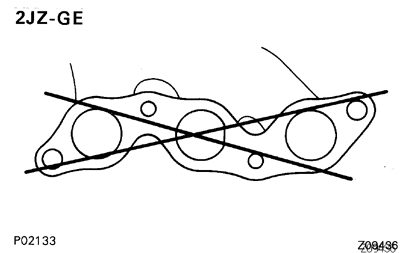

Inspect air intake chamber

Using a precision straight edge and feeler gauge, measure the surfaces contacting the intake manifold for warpage.

Maximum warpage: 0.15 mm (0.0059 in.)

If warpage is greater than maximum, replace the chamber.

-

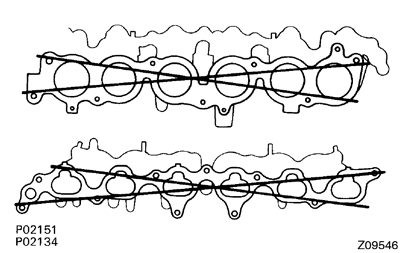

Inspect intake manifold

Using a precision straight edge and feeler gauge, measure the surfaces contacting the cylinder head and air intake chamber for warpage.

Maximum warpage: 0.15 mm (0.0059 in.)

If warpage is greater than maximum, replace the manifold.

-

Inspect exhaust manifold

Using a precision straight edge and feeler gauge, measure the surfaces contacting the cylinder head for warpage.

Maximum warpage: 0.80 mm (0.0315 in.)

If warpage is greater than maximum, replace the manifold.

-

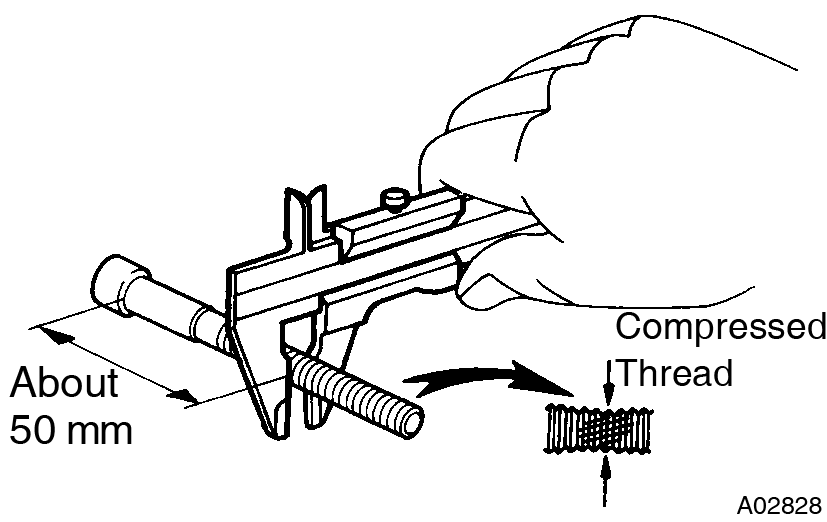

Inspect cylinder head bolts

Using a vernier caliper, measure the thread outside diameter of the bolt.

Standard outside diameter:

10.8 - 11.0 mm (0.425 - 0.433 in.)

Minimum outside diameter: 10.7 mm (0.421 in.)

If the diameter is less than minimum, replace the bolt.

This guide is based on the book edition Toyota (RM502U, 1997)

Volksbibliothek, info@volksbibliothek.com

Back Next