Engine unit installation

-

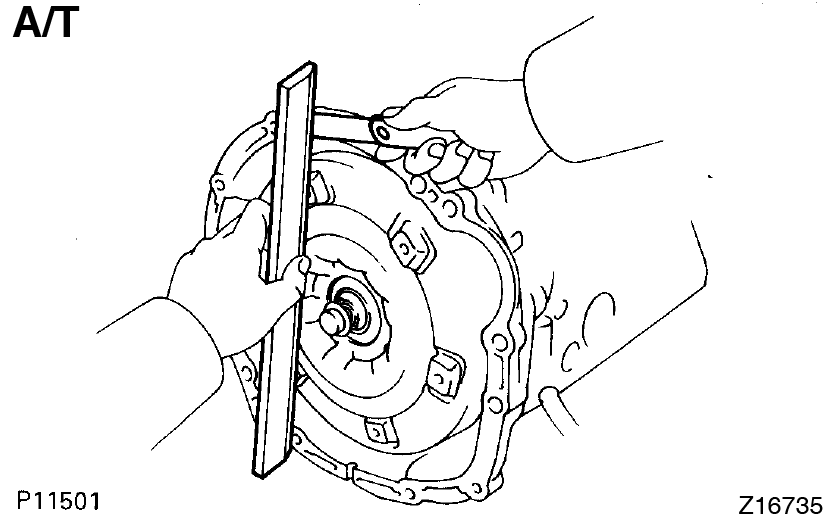

A/T:

Check torque converter clutch installation

Using calipers and straight edge, measure from the installed surface of the torque converter clutch to the front surface of the transmission.

Correct distance: Less than 0.1 mm (0.004 in.)

If the distance is not as specified, check for an improper installation.

-

Assemble engine and transmission

-

M/T:

Align the input spline with the clutch disc and install the transmission to the engine. - Align the 2 knock pins on the cylinder block with the pin holes of the clutch housing.

-

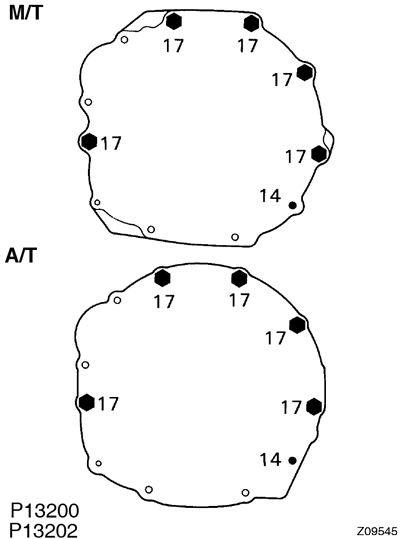

Install the transmission with the 6 bolts.

Torque:

14 mm head 39 N·m (400 kgf·cm, 29 ft·lbf)

17 mm head 72 N·m (730 kgf·cm, 43 ft·lbf)

-

M/T:

-

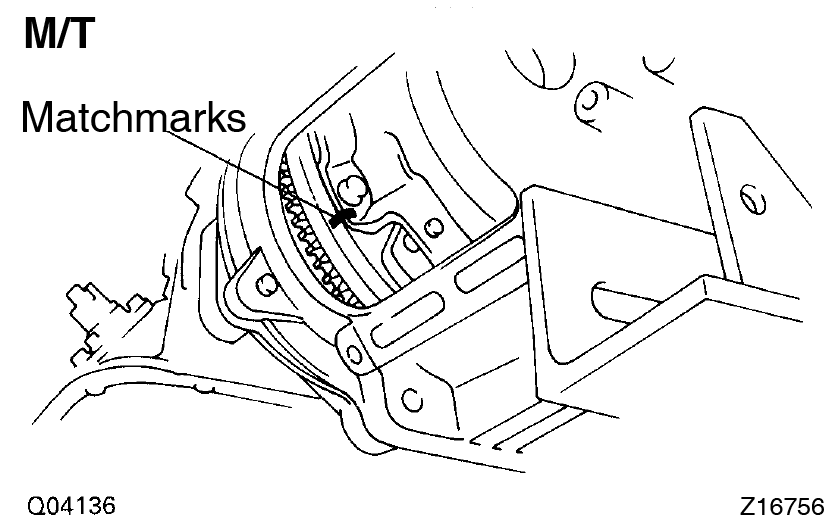

M/T:

Install clutch cover set bolts

- Align the matchmarks.

-

Install the 6 bolts while turning the crankshaft to gain access. Tighten the bolts evenly.

Torque: 19 N·m (195 kgf·cm, 14 ft·lbf) -

Install the service hole cover with the 2 bolts.

Torque: 12 N·m (120 kgf·cm, 9 ft·lbf)

-

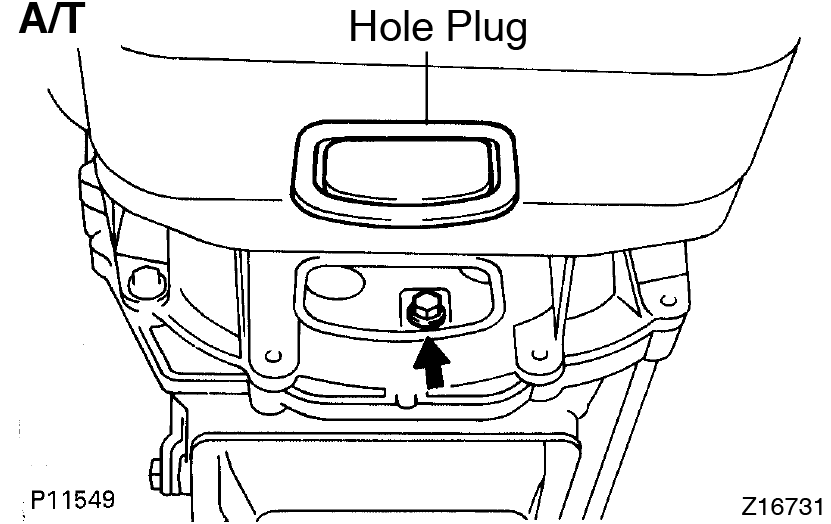

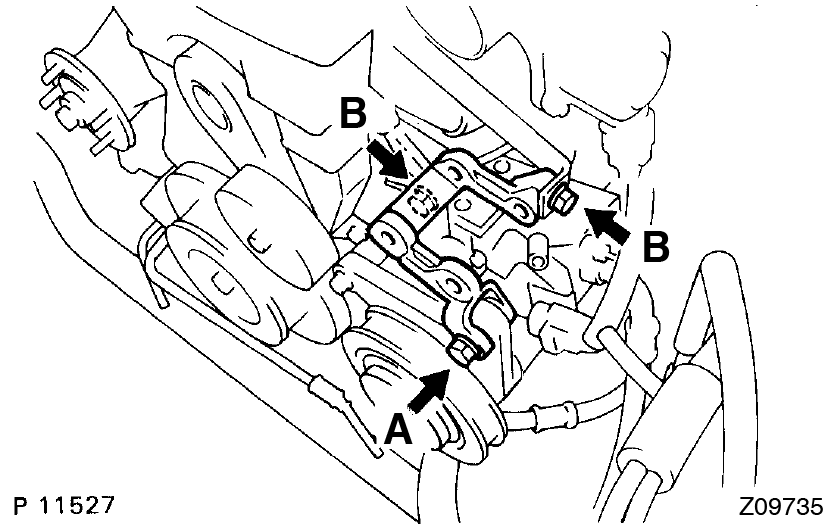

A/T:

Install torque converter clutch mounting bolts

-

First, install the gray bolt. Then install 5 black bolts while turning the crankshaft to gain access. Tighten the bolts evenly.

Torque: 33 N·m (340 kgf·cm, 25 ft·lbf) - Install the hole plug.

-

First, install the gray bolt. Then install 5 black bolts while turning the crankshaft to gain access. Tighten the bolts evenly.

-

A/T:

Install oil cooler pipe for transmission- Temporarily install the 2 oil cooler pipe, 2 hose clamps and tube clamp with 3 clamp bolts.

-

Connect the 2 oil cooler tubes to the unions on the transmission. Tighten the union nuts.

Torque:44 N·m (450 kgf·cm, 33 ft·lbf) - Tighten the 3 clamp bolts.

- Install starter

- Connect engine wire to transmission

-

A/T:

Install oil dipstick and guide for transmission- Install a new O-ring to the dipstick guide.

- Connect the dipstick guide end to the dipstick tube of the oil pan.

- Install the dipstick guide with the bolt.

- Install the dipstick.

-

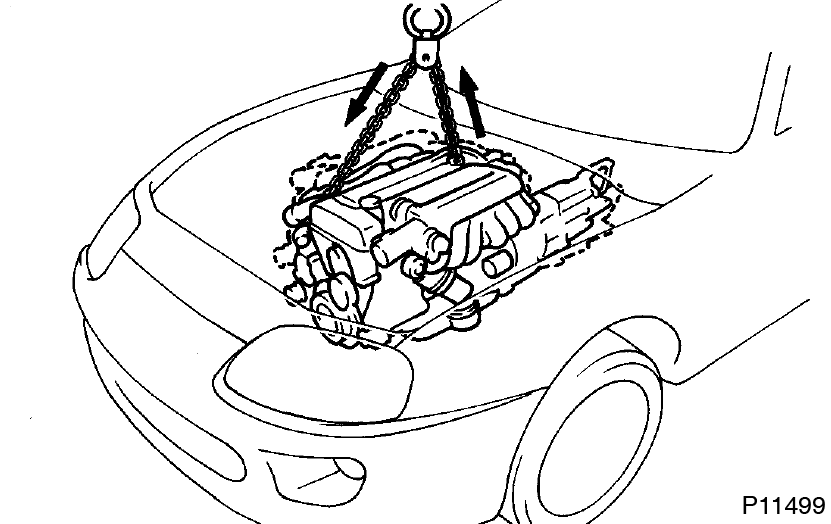

Install engine and transmission assembly in vehicle

- Attach the engine hoist chain to the engine hangers.

-

Lower the engine and transmission assembly into the engine compartment.

Install the engine and transmission assembly carefully without damaging the shift lever retainer (M/T), A/C compressor and PS solenoid valve.

-

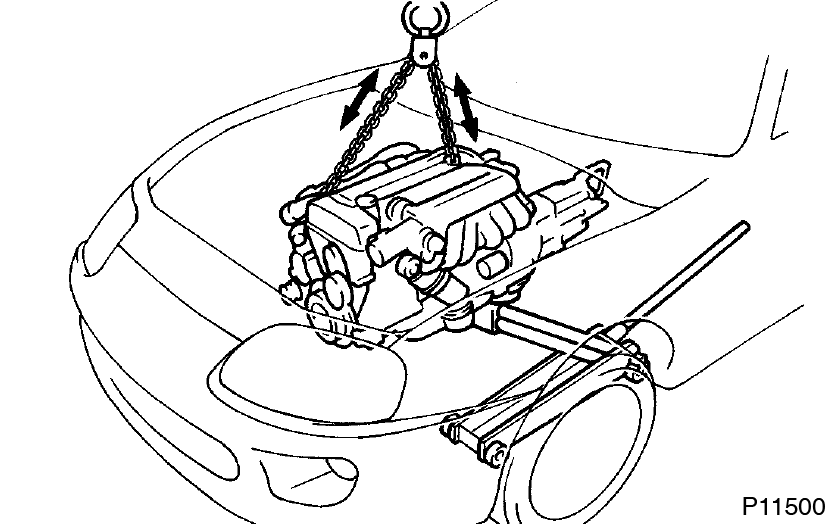

Insert the stud bolts of the front engine mounting insulators into the stud bolt holes of the front suspension crossmember.

- Temporarily install the 2 nuts holding the engine front mounting insulators to the front suspension crossmember.

- Keep the engine level with a jack.

- Remove the hoist chain.

-

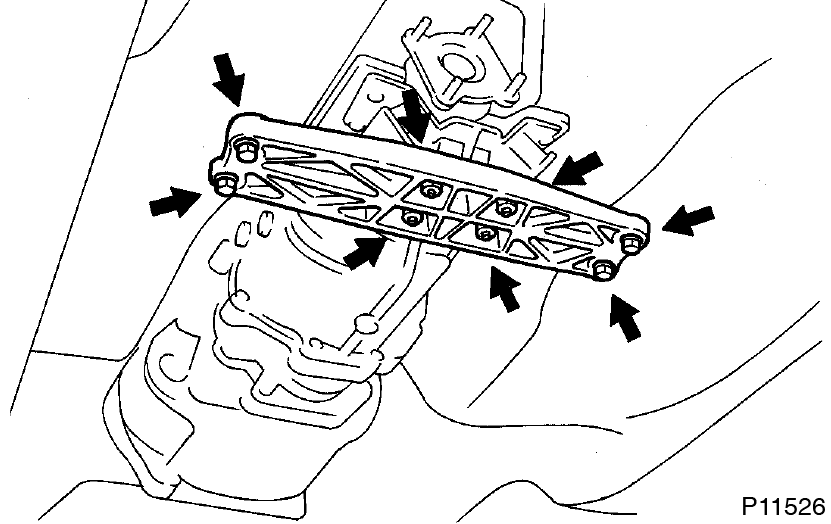

Temporarily install the support member to the engine rear mounting insulator with the 4 nuts.

-

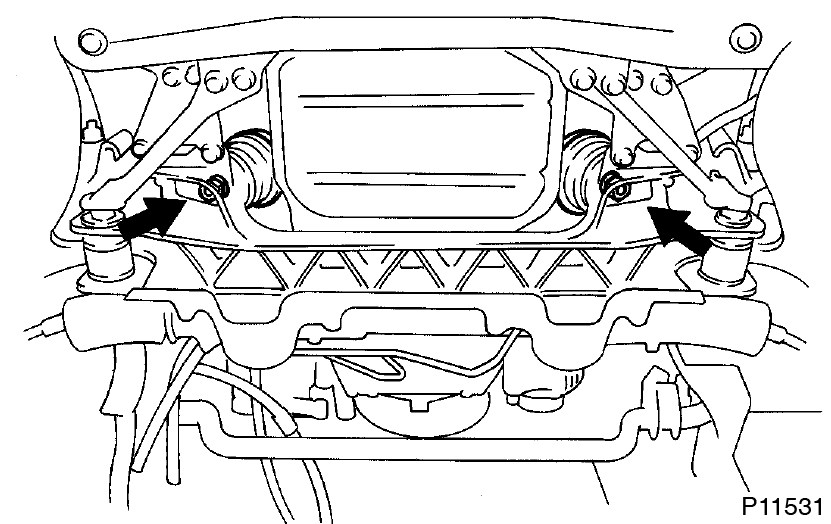

Install the 4 bolts holding the support member to the body.

Torque: 25.5 N·m (260 kgf·cm, 19 ft·lbf) -

Tighten the 4 nuts holding the support member to the engine rear mounting insulator.

Torque: 13 N·m (135 kgf·cm, 10 ft·lbf) -

Tighten the 2 nuts holding the engine front mounting insulators to the front suspension crossmember.

Torque: 59 N·m (600 kgf·cm, 43 ft·lbf)

-

M/T:

Install transmission shift lever

Torque: 19 N·m (195 kgf·cm, 14 ft·lbf) -

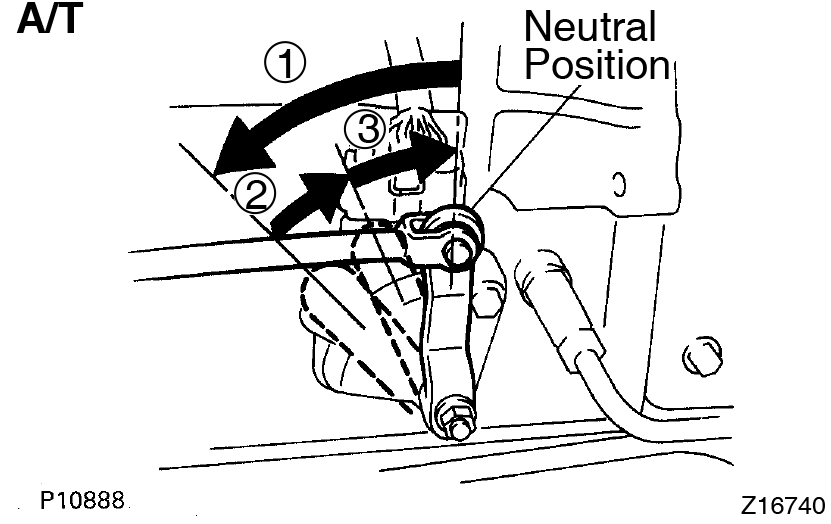

A/T:

Connect transmission control rod

- Shift the shift lever to N position.

- Fully turn the control shaft lever back and return 2 notches. It is now in neutral position.

-

Connect the control rod to the shift lever with the nut.

Torque: 13 N·m (130 kgf·cm, 9 ft·lbf)

- Install propeller shaft (See page PR-11)

-

Install rear center floor crossmember brace

Torque: 28 N·m (290 kgf·cm, 21 ft·lbf) - Install exhaust pipe heat insulator

-

Install No.2 front exhaust pipe

Install a new gasket and the front exhaust pipe with 3 new nuts.

Torque: 62 N·m (630 kgf·cm, 46 ft·lbf) -

Install exhaust pipe assembly

- Install the hook of the tailpipe to the 2 rings on the tailpipe bracket.

- Install the hook of the exhaust pipe to the 2 rings on the exhaust pipe brackets.

-

Install the pipe support bracket with the 2 bolts.

Torque: 43 N·m (440 kgf·cm, 32 ft·lbf) -

Install a new gasket and the No.2 front exhaust pipe to the front exhaust pipe with the 2 bolts and 2 new nuts.

Torque: 58 N·m (590 kgf·cm, 43 ft·lbf)

-

Install heated oxygen sensor

Install a new gasket, the oxygen sensor and sensor cover with the 2 nuts.

Torque: 20 N·m (200 kgf·cm, 14 ft·lbf) -

M/T:

Install clutch release cylinder and ground strap-

Install the clutch release cylinder with the 2 bolts.

Torque: 13 N·m (130 kgf·cm, 9 ft·lbf) -

Connect the clutch line tube with the bolt.

Torque: 37 N·m (380 kgf·cm, 27 ft·lbf) -

Install the ground strap with the bolt.

Torque: 37 N·m (380 kgf·cm, 27 ft·lbf)

-

Install the clutch release cylinder with the 2 bolts.

-

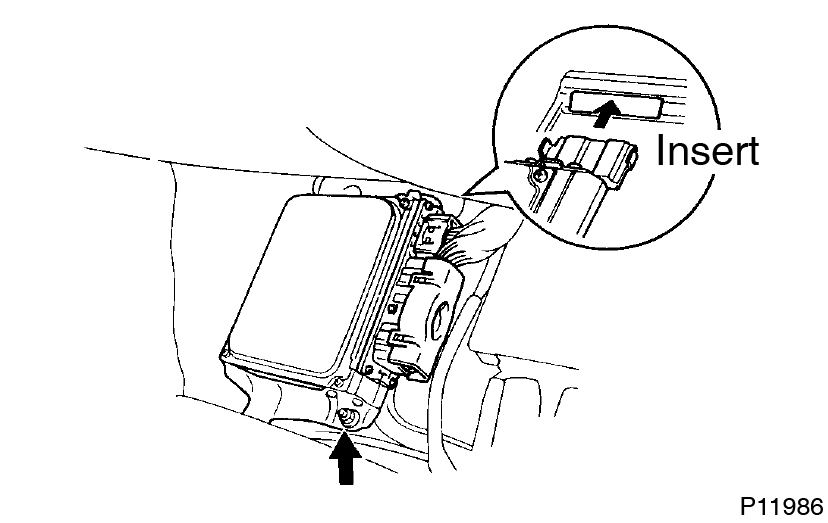

Connect engine wire to cabin

-

Push in the engine wire through the cowl panel.

Be careful not to damage the engine wire.

- Connect the 2 connectors to the connector cassette.

- Connect the connector to the instrument panel wire connector.

- Connect the 2 connectors to the ECM.

- Connect the connector to the TRAC ECU.

- Insert the ECM bracket into the stay on the floor panel.

- Install the ECM with the nut.

- Install the ECM protector with the 2 nuts.

- Install the floor carpet.

- Install the scuff plate.

-

Push in the engine wire through the cowl panel.

-

M/T:

Install upper console panel, shift lever boots and holding bolts - Connect engine wire to cowl panel

-

Install A/C compressor

-

Using a torx socket (E10), install the stud bolt and compressor.

Torque: 26 N·m (265 kgf·cm, 19 ft·lbf) - Connect the compressor connector.

- Temporarily install the compressor with nut and 3 bolts.

-

Alternately tighten the bolt and nut.

Torque: 52 N·m (530 kgf·cm, 38 ft·lbf)

-

Using a torx socket (E10), install the stud bolt and compressor.

-

Install PS pressure feed hose

Install the pressure feed hose with the 2 clamp bolts. -

Install PS pump

-

Install the pump bracket with the 3 bolts.

Torque:- 58 N·m (590 kgf·cm, 43 ft·lbf)

- 39 N·m (400 kgf·cm, 29 ft·lbf)

-

Install the vane pump with the 2 bolts.

Torque: 58 N·m (590 kgf·cm, 43 ft·lbf) -

Connect these hoses:

- PS air hose to throttle body

- PS air hose to air intake chamber

-

Install the pump bracket with the 3 bolts.

-

Connect fuel hoses

- Connect the fuel return hose to the fuel return pipe.

- Install the fuel return hose to the clamp of the dipstick guide.

-

Install the fuel inlet hose with 2 new gaskets and the union bolt.

Torque: 29 N·m (300 kgf·cm, 22 ft·lbf)

- Connect wires and connectors

- Connect evap hose

- Connect brake booster vacuum hose

- Connect heater water hoses

- Install charcoal canister

- Install water pump pulley, fan, fluid coupling assembly and drive belt (See page CO-11)

-

M/T:

Install drive belt tensioner damper (See page EM-21 ) - Install air cleaner and MAF meter assembly

- Install No.1 air hose

- Connect control cables to throttle body

- Fill with engine oil

- Install radiator assembly (See page CO-28 )

- Start engine and check for leaks

- Install hood

-

Road test

Check for abnormal noise, shock slippage, correct shift points and smooth operation. - Recheck engine coolant and engine oil levels

This guide is based on the book edition Toyota (RM502U, 1997)

Volksbibliothek, info@volksbibliothek.com

Back Next